Meet the STORM.

“Surface Transformation Of Raw Materials”

At the core of LAYRR is our proprietary platform

While others rely on wet chemistry or small-scale lab experiments, we have built a validated industrial rig capable of processing 50kg+ batches today. The STORM uses Physical Vapour Deposition (PVD) to decouple a material’s surface properties from its core, creating high-value hybrid powders.

Why The STORM Changes Everything:

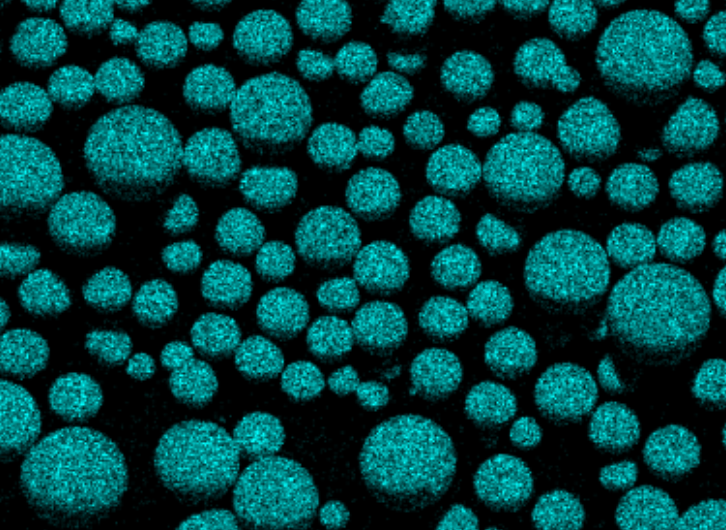

Atomic Precision: We achieve uniform coatings on particles as small as 5µm. This allows us to "thrift" expensive materials by placing them only where they are needed on the surface.

Zero-Waste Manufacturing: Our process is entirely solvent-free. We eliminate the environmental burden of wet chemistry, offering a cleaner, sustainable manufacturing route for advanced materials.

Validated Scalability: This is not a concept. It is a running industrial machine delivering consistent results for magnets, batteries, and aerospace shielding.

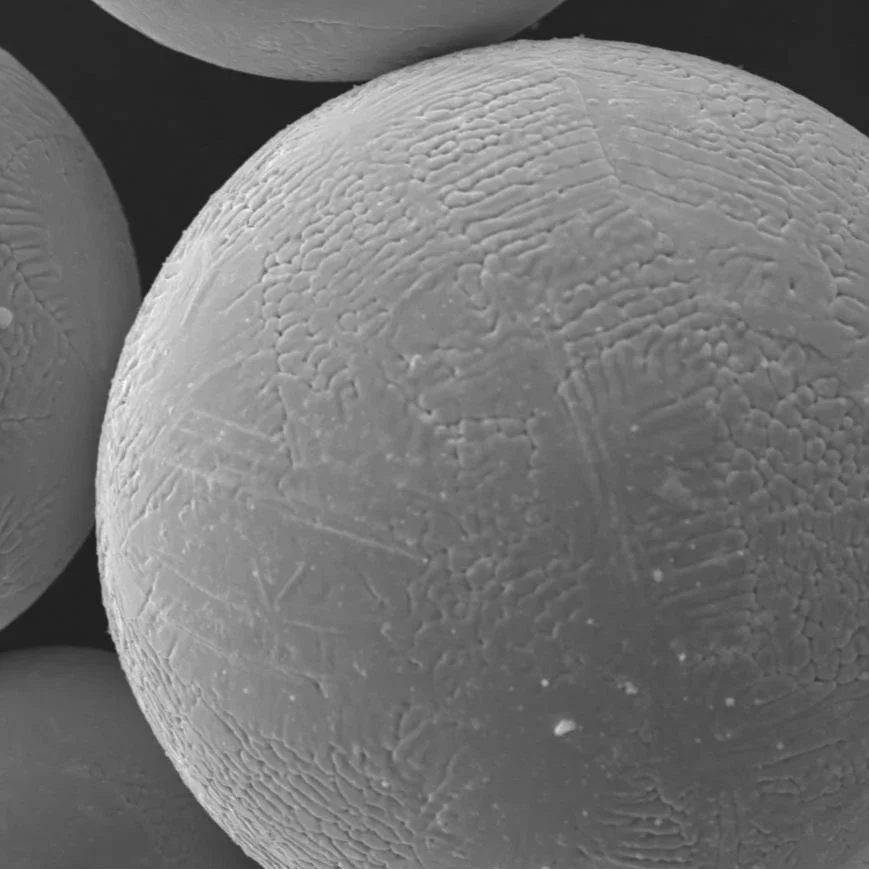

Solving the "Shadow" Problem

Standard PVD cannot coat a pile of powder; it only coats the top layer, leaving the rest in the dark. The STORM utilizes a proprietary agitation and handling system that ensures every single particle is continuously exposed to the coating flux.

Encapsulation, not just coverage: We achieve a true core-shell structure where the coating is uniform across 100% of the particle's surface area.

High-Energy Adhesion: unlike wet-chemical coatings which often rely on weak van der Waals forces, our PVD process launches atoms at high energy, creating superior adhesion between the core and the shell.

Why This Matters (The Benefits)

Solvent-Free Purity: We bring the cleanliness of the semiconductor industry to bulk materials. No binders, no solvents, no drying steps. Just the pure material, atomically bonded.

Thrifting at Scale: Because we can handle bulk powder, we make it economically viable to use precious metals (Gold, Platinum, Silver) in industrial applications by applying them only as a thin skin.

Tunable Thickness: From a 5nm "flash" coating to a robust 5µm functional shell, the process is fully controllable.

Particle Versatility: From Micron to Millimetre

Handling powder in a vacuum is notoriously difficult. Fine powders clump; heavy granules break. The STORM features an adaptive handling architecture capable of processing the full spectrum of industrial feedstocks:

The Challenge of the Micron (5µm - 20µm): Fine powders act like fluids and are prone to agglomeration. Our system overcomes cohesive forces to coat individual grains without clumping.

The Challenge of the Millimetre (500µm+): Larger granules behave differently under gravity. We can coat robust substrates for improved wet ability, flow ability, and property improvements without attrition or damage to the particle.