Innovation

at the Surface

Next-generation industrial materials created through atomic level surface engineering.

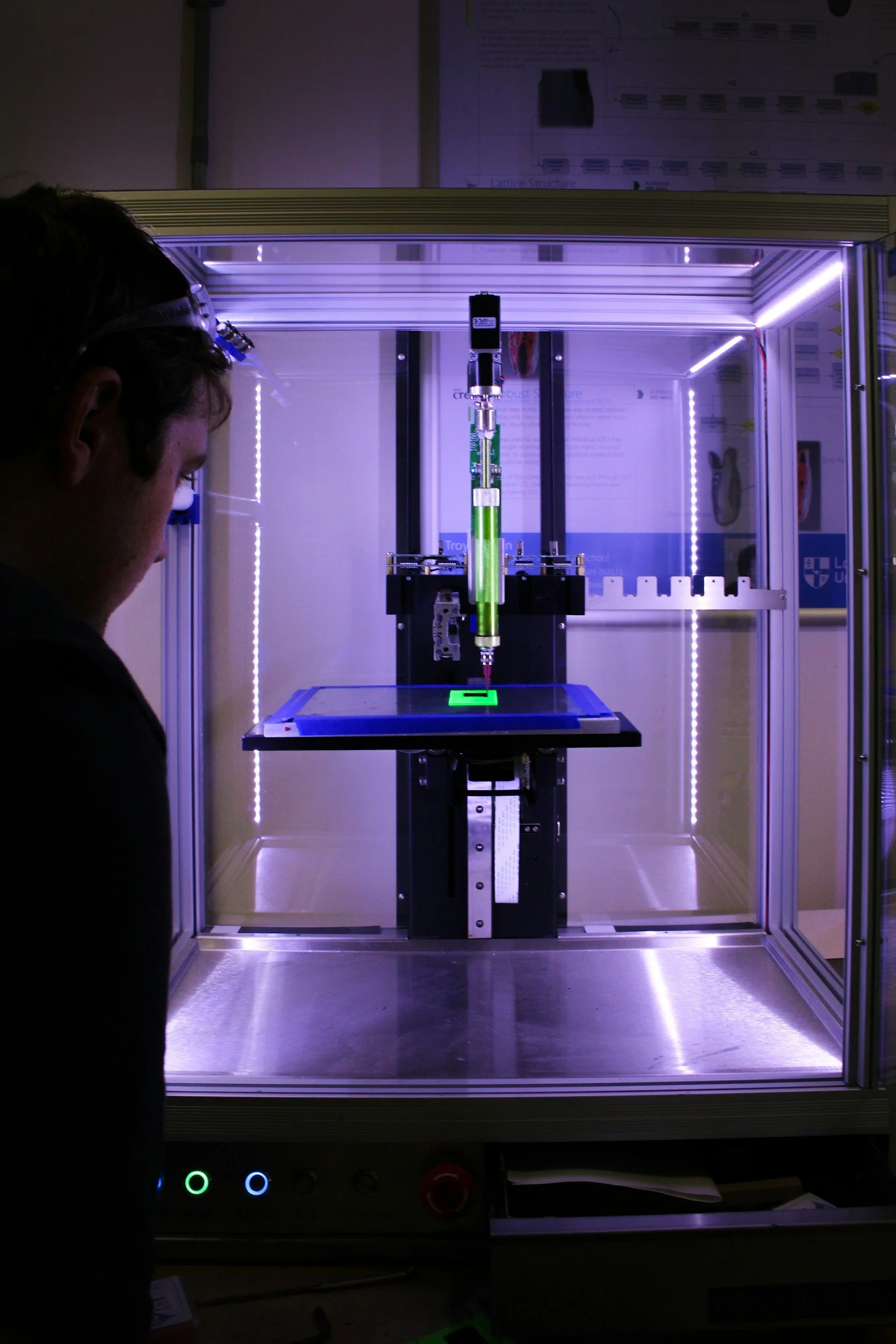

LAYRR uses a clean, precise and fast process to add ultra-thin nano-coatings to commodity powders, giving them enhanced functionality and boosted performance while significantly reducing dependence on critical metals.

Functional Capabilities:

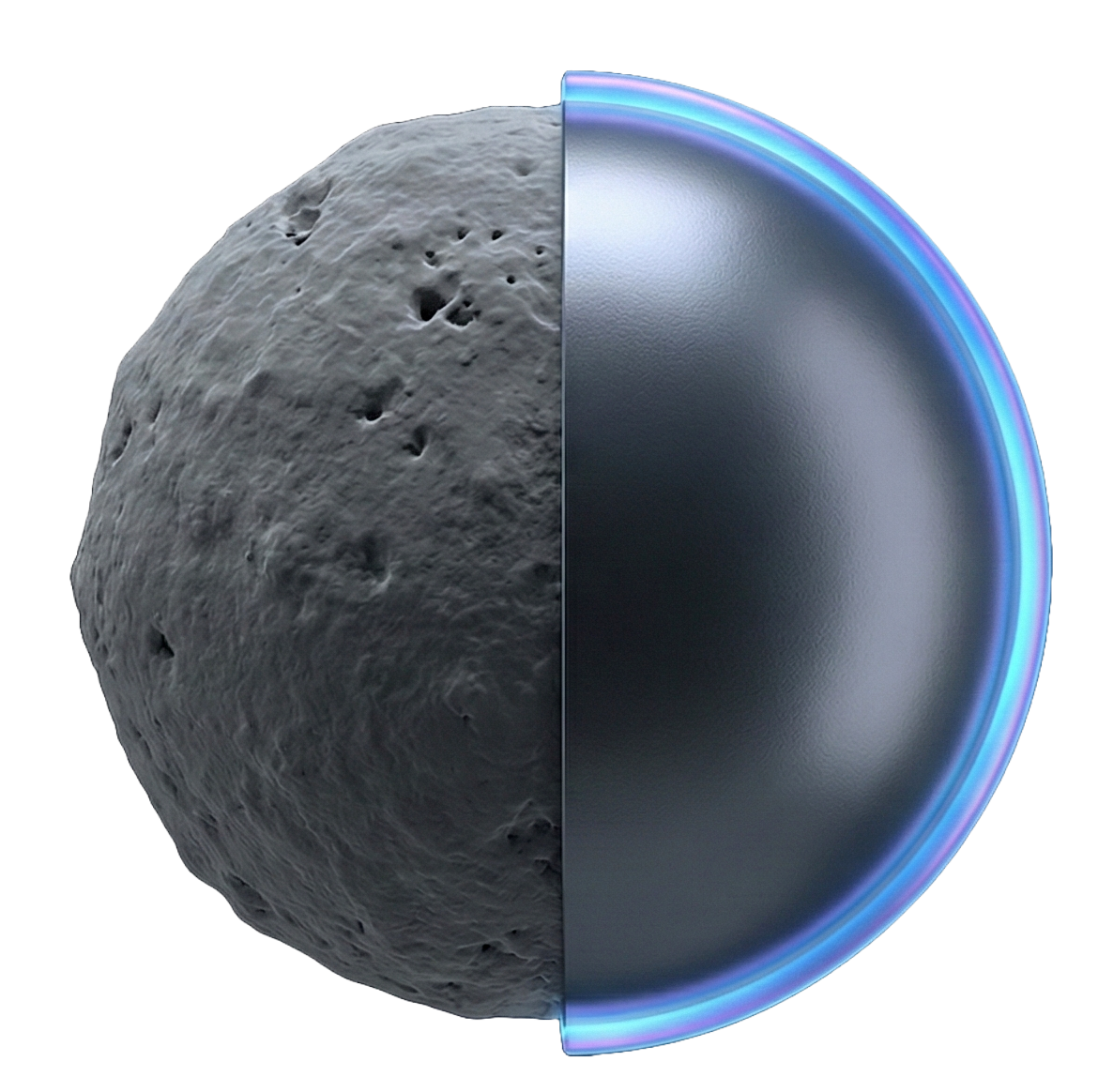

Engineering the Particle Surface

We don't just coat materials; we fundamentally alter how they interact with the world. By decoupling surface properties from the core material, LAYRR allows for the creation of hybrid powders that solve conflicting engineering constraints.

Energy Transfer

Turning insulators into conductors, and heavy shields into lightweight solutions.

Electrical Conductivity: We can apply highly conductive metals (Copper, Silver) onto non-conductive ceramic or polymer cores. This enables the creation of conductive pastes and inks using significantly less precious metal.

EMI/RFI Shielding: Traditional shielding is heavy. We produce lightweight radar-absorbing materials by coating ultra-light substrates with conductive copper. This provides high-performance electromagnetic interference shielding for aerospace and defence applications without the weight penalty of solid metal.

Battery Performance: We engineer the surface of anode and cathode powders to enhance electron transport and protect against degradation, directly improving cycle life and charge rates.

Mechanical Performance

Harder, stronger, and more durable interfaces.

Wear Resistance: We deposit hard, tribological coatings onto softer core particles. This protects the particle during processing or within a matrix, extending the lifespan of the final component.

Interface Strength in Composites: In Metal Matrix Composites (MMCs) or reinforced polymers, the failure point is often the interface between the particle and the matrix. We engineer the surface chemistry to maximise adhesion, resulting in superior tensile strength and load transfer.

High Entropy Alloys (HEAs): We are successfully processing High Entropy Alloy powders, enabling next-generation mechanical properties for extreme environments that traditional metallurgy cannot achieve.

Cost & Bulk Reduction ("Thrifting")

Strategic use of precious materials.

The Core-Shell Advantage: Why use a solid silver particle when the conductivity happens only at the surface? We coat inexpensive cores (like stainless steel or silica) with a nanometric layer of precious metal.

Massive Material Savings: This "thrifting" approach reduces the consumption of critical raw materials (Silver, Platinum, Gold) by up to 90% while maintaining the required functional surface properties.

Lightweighting: By using low-density cores (like aerogel or polymers) with functional metallic skins, we drastically reduce the bulk density of the powder, vital for aerospace and automotive applications.

Flowability & Process-ability

Optimising powders for manufacturing.

Additive Manufacturing (AM): Creating consistent, uniform flows in 3D printers is critical. Our atomic-level precision ensures uniform surface roughness and chemistry, preventing clumping and ensuring smooth flow in powder bed fusion processes.

Dispersibility: For paints, pastes, and inks, we engineer the surface energy of the powder to ensure perfect wetting and dispersion within the solvent or binder, eliminating agglomeration.

Thermal Management

Controlling heat at the micro-scale.

Thermal Conductivity: Enhance the heat transfer capabilities of polymer composites by incorporating ceramic powders coated in conductive metals.

Thermal Barriers: Conversely, we can apply thermal barrier coatings to metal powders used in additive manufacturing, allowing the final parts to withstand higher operating temperatures in turbine and engine applications.